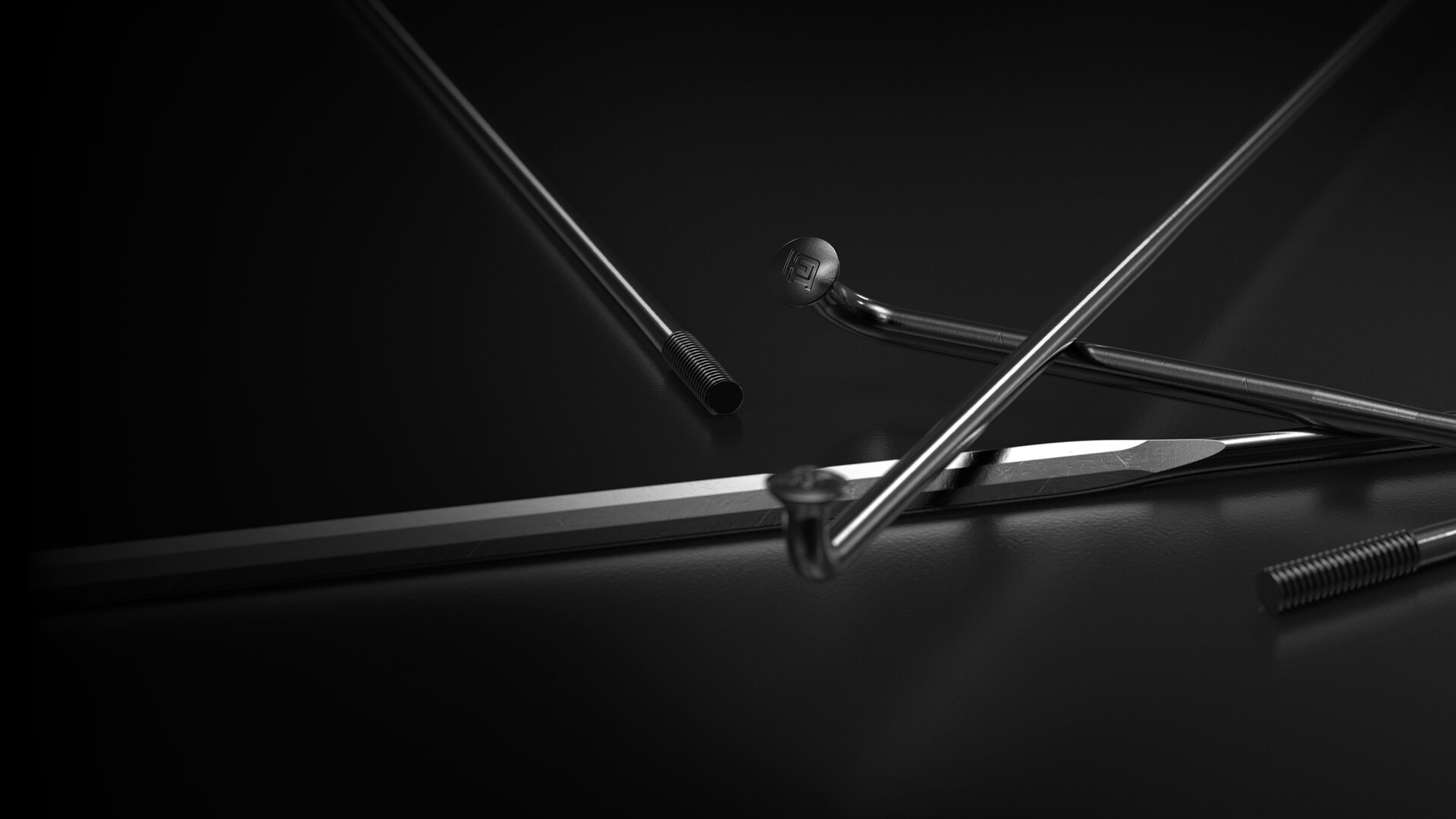

The production of high-quality spokes marked the beginning of the company. DT was synonymous with top quality Swiss spokes, even before the establishment of today‘s DT Swiss AG. To this day, DT Swiss spokes stand for durability and precision and are unrivalled thanks to their unique production process that combines lightweight with durability.

Spoke

technology

Producing your spokes, step by step.

Steel raw material

Steel alloy specifically developed for spoke manufacturing is acquired from select wire suppliers. This raw material must be of a high quality, which is consistently controlled.

A specific alloying of the steel allows the wire to be further processed to the required strength and elongation properties of the spoke wire. Quality control is essential here to ensure the delivered raw material is in accordance with the specifications required by DT Swiss for composition and quality.

Raw wire materiaL

The 18/10 stainless steel spoke wire undergoes bending and tensile tests at the outgoing department of the supplier. The spoke wire is wound into coils of approx. 800-900 kg and are delivered in 4 different diameters: 1.8, 2.0, 2.15 and 2.34 mm. The close exchange and coordination of quality control between DT Swiss and the wire supplier make sure the tight surface tolerances of the diameter and the ovality of the wire are maintained. By complying with the specifications, efficient and machine-friendly production of the spokes can be guaranteed. The outgoing goods inspection of the supplier is identical to the incoming goods inspection of DT Swiss. To ensure a consistent surface, the incoming wire is analyzed for surface irregularities. Human touch and experience are also essential aspects in ensuring quality, therefore every wire coil is checked by hand to detect any irregularities. The diameter and the ovality are then controlled with a micrometer.

Spoke wire straightening

The wire is unwound directly from the coils and straightened by machine for further processing. This step is performed for all types of spokes and results in straight spoke blanks precisely cut to length in the hundredths range. Here not only controlling the material and the machine is important, but also the tools and their degree of wear. Each machine in the production process is checked twice a day with different measuring devices featuring tight tolerances to ensure a constant quality and finish of the material. This control is very important for the smooth flow of the subsequent processing steps.

Cold forging

This process, which was developed and patented by DT Swiss, is used to reduce the desired diameter of the spokes. By rotating oscillating hammers around the wire, the spoke blank is compressed and reduced in diameter, which also densifies the material for higher strength. This process results in a spoke that is both light and strong, with a butted elastic part for lightweight and a firmer head and thread for higher load capacity.

Thanks to the cold forging process, the material is strengthened while retaining good elongation properties. The transition from a reduced to unreduced diameter of a spoke is extremely harmonious and generates a high-quality appearance. Before the next step, a selection of spokes are hand-checked for straightness, diameter and ovality.

Forming head and thread

As the steps progress, the product gets closer to its known form. The spokes are cut to an exactly calculated and desired length. Directly thereafter, the spoke head is embossed together with the unique “DT” symbol. Classic spokes are additionally cranked in a 90-95° angle to get the J-shape head. At the other end of the spoke blank, the thread is formed in the rolling process, this ensures that no material is removed, unlike the thread cutting process, to keep and improve its strength.

Several checks are then performed on the spokes. A visual inspection of the spoke head ensures that the logo is visible and that the material has no defects on its angle. The head diameter, angle length and thread (length and diameter) are measured with a digital caliber. The spoke thread faces a manual function test. This series of tests is performed every 35 minutes on at least one spoke.

Flat forging

Semifinished (butted or straight-gauge) spokes are bladed during this process with a weight of up to 250 tons. This flat shape of the spoke provides particularly aerodynamic advantages. The forging process densifies the material even more, which in turn achieves a greater strength. An inspection of each spoke is made to ensure the correct length and flatness; this quality control is performed every 15 minutes.

Spoke blackening

For aesthetic reasons, the spokes can also be blackened. Although it may seem simple, this blackening process is quite specific to ensure that coloring of the spokes does not add extra weight or performance penalties. For each order, a selection of spokes is tested on the quality of blackening to ensure optimal resistance even after several years. Approximately 85 % of the produced spokes leave the factory in black color.