less wear

With the use of a single cylindrical spring, the system wears less while allowing faster full engagement.

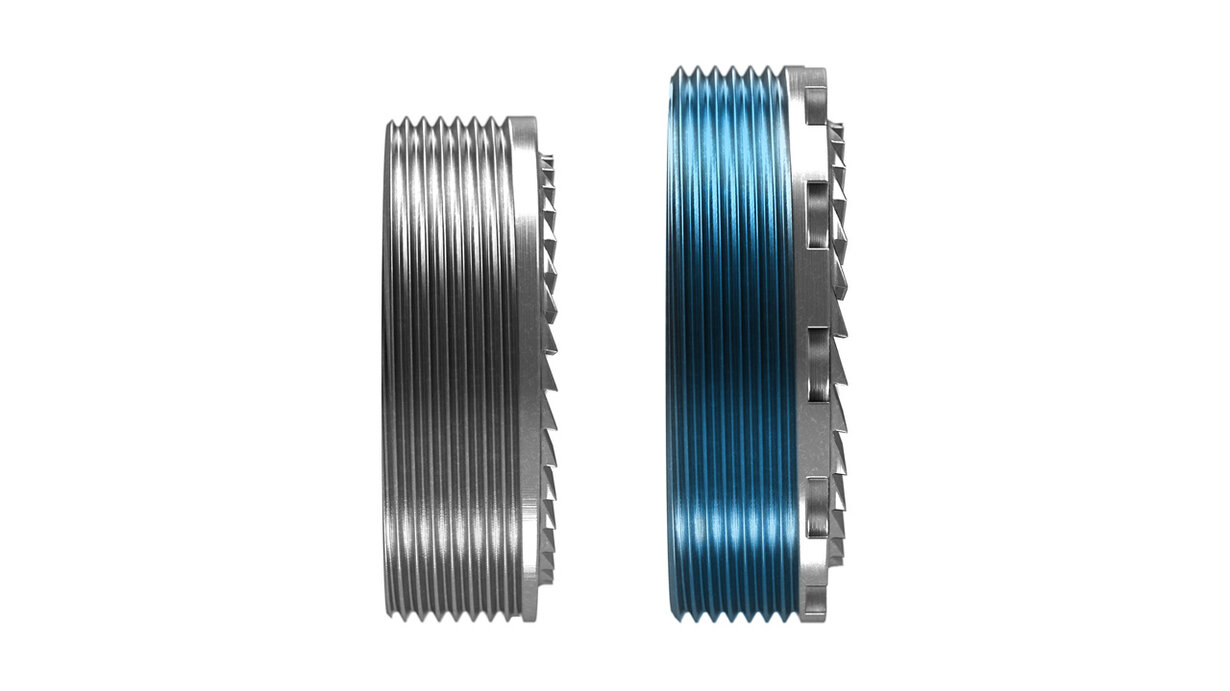

Learn moreBased on the Ratchet EXP system, the Ratchet EXP OS also connects the ratchet to the hub by integrating the threaded ring with the ratchet. This allows for the use of a single spring, which improves engagement accuracy as the ratchets are consistently at the correct angle.

Superior Reliability

With full 30T engagement, the force generated by the motor and rider is transmitted evenly over a wide contact area, allowing for superior reliability.

Learn moreThe Ratchet EXP OS increases the number of teeth from 24 in the conventional system to 30, which in turn reduces the angle of engagement. On the eMTB, where there is a certain amount of free movement of the cranks due to the motor, this provides a small advantage. To ensure the reliability of the system, the Ratchets are made of steel for reduced wear, resulting in better durability.

bigger Threaded Ring

A bigger double thread spreads the loads across a larger area, reducing peak loads, contributing to the longevity of the system and even allowing more torque to be transmitted.

Learn moreThe surface of the Ratchet EXP OS double thread is 11% larger than the regular Ratchet EXP thread. A double thread means that the thread has two starts and two threads. Thus, in one turn, a screw with two threads advances twice as far as a screw with one thread.

Bigger Bearings

Larger bearings with larger balls spin fast and better absorb the additionnal axial and radial loads from the eMTBs.

Learn moreOn account of the greater loads on eMTBs, the new generation of Hybrid wheels use larger ball bearings than the 240 EXP MTB hub. The larger ball bearings distribute loads over a larger area of the running surface, whereby less wear occurs.

purpose-built Axle

The axle was tested in FEM-strength analyses in order to determine the bending loads that occur when riding an eMTB and to optimize the axle resistance.

Learn moreThe FEM analysis enabled axle optimisation by simulating its structure under a specific load case to identify the location of the bending loads occuring on the axle. Once located, these loads can be distributed uniformly across the axle by adding more material at the right place: the ball bearing area.

ratchet exp os

The new Ratchet EXP OS technology can be found in these products: